Brick masonry is the most used structural technique in house construction. In brick masonry, the bricks are arranged in a systematic pattern, and the joints are filled with mortar to make a solid structure.

Brick is a versatile building material used in commercial and residential construction. This technique has many benefits. By this, the building will be perfect in structure and lasts for a long time. Many types of bricks and several methods of brick masonry are present in the house construction industry.

In the below article, we will learn about Brick masonry in India, Types of bricks used in masonry construction, Types of Bonds in Brick Masonry & Types of masonry in construction.

Based on its manufacturing method, bricks are vividly divided into two – sun-dried or unburnt bricks and burnt bricks, along with other varieties.

Sun-dried or unburnt clay bricks are comparatively less durable. These are used for temporary construction structures. The manufacturing process of these bricks involves three steps: preparation of clay, moulding, and drying. After moulding, the bricks are directed to dry in the sunlight. Hence, they are not strong and have less water and fire resistance.

They are bricks of excellent quality yet also include defected bricks. Burnt bricks are classified into four: first-class, second, third, and fourth. Most house construction companies use burnt bricks for construction.

These are good quality bricks than others. Since they are molded by table molding and burnt in large kilns, first-class bricks are of standard shape, with smooth surfaces and sharp edges. They are durable and strong, and it also used in permanent structures. They are costly because of their good qualities.

They are of moderate quality and are also burnt in kilns. They are molded by the ground-molding method and thus do not possess smooth surfaces or sharp edges and have an irregular shape. Yet they perform strength and durability.

They are poor-quality bricks and are used in the construction of temporary structures. These bricks are not good for rainy areas. The surface would be rough and have unfair edges.

These are very poor-quality bricks and not directly using in construction. They are crushed and used in concrete manufacturing.

These bricks are produced using fly ash and water. They have properties better than clay bricks. They contain a huge amount of concentrated calcium oxide that can be used to produce cement. Hence it is also known as self-cementing brick. They have high fire insulation, high strength, and lower water penetration, and soaking is not necessary.

They are made up of concrete with ingredients like cement, sand, coarse aggregates, and water. They can be manufactured in different sized. Concrete bricks can be manufactured at construction sites, require less quantity of mortar, and can be pigmented.

Sand lime or calcium silicate bricks are made up of sand and lime. In construction, they are used for several purposes, such as ornamental works, masonry works, and all.

Some most commonly used bonds in brick masonry are,

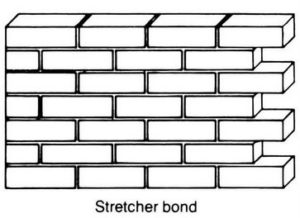

Stretcher bond, also referred to as running bond, occurs when bricks are aligned with only their stretchers visible. The long narrow face of the brick is called a stretcher, and a stretcher bond is the simplest brick repeating pattern. They are used for one-half brick-thick walls since they cannot make effective bonding with adjacent brick in full-width brick walls.

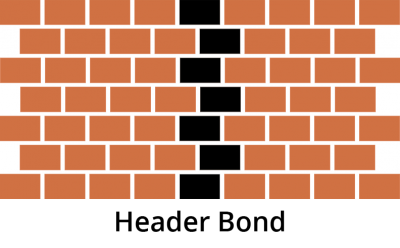

The header is the short square side of the brick that measures 9cm x 9cm. In the header bond, also known as the heading bond, the bricks are placed as headers on the wall faces, and the header bond is used to build walls with full brick thickness.

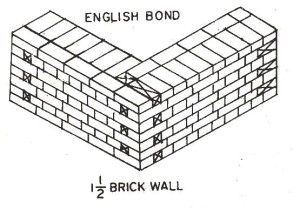

This type of bond has only one course of stretcher and a course of header above it. Headers are placed on the center of stretchers in the course below, and each substitute raw is vertically aligned. A Quoin closer is used in the start and end of a wall to break the continuity of vertical joints.

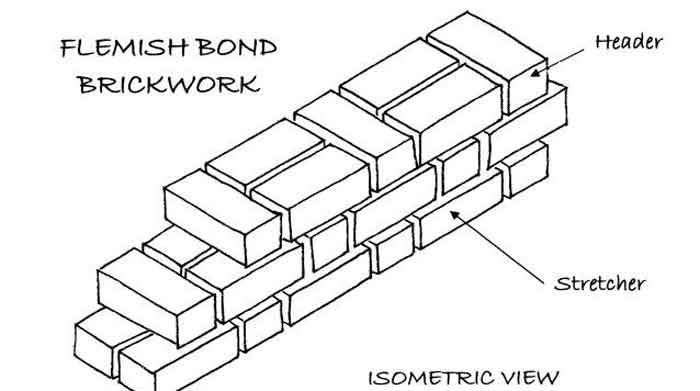

Flemish bond, also known as Dutch bond, is created by arranging repetitive course headers and stretchers. The thickness of the Flemish bond is a minimum of one full brick. The disadvantage of this bond is that the construction could be easier and needs good skill to arrange it properly.

There are other different types of masonry in construction based on building materials.

The most durable, strong, and weather-resistant building material is stone. Hence masonry is least affected by daily wear and tear than others. Stone masonry structures have a life span of 300 to 1000 plus years.

Stone masonry is divided into two categories- rubble masonry and ashlar masonry.

Rubble masonry is further categorized into uncoursed or coursed random rubble masonry, uncoursed or coursed square masonry, polygonal rubble masonry, and dry rubble masonry.

Ashlar masonry is again divided into fine ashlar masonry, ashlar block in course, ashlar chamfered masonry, and ashlar rough tooled masonry.

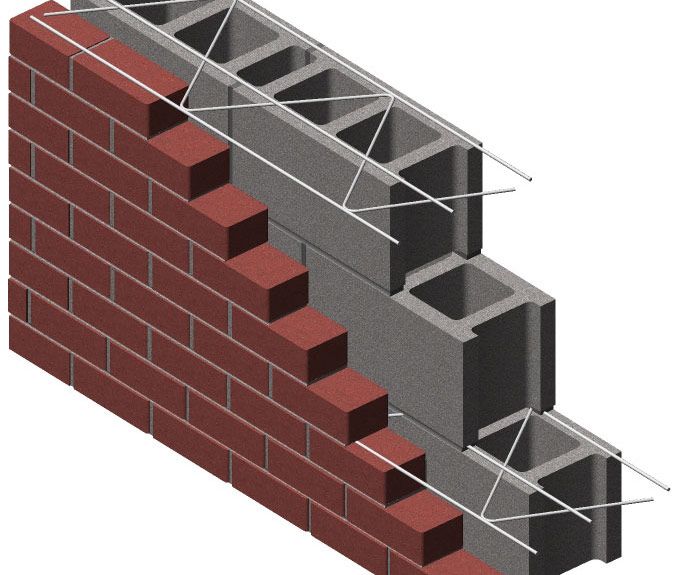

In this construction type, the concrete blocks are compressed on top of others, like in brick masonry. The time required to lay concrete blocks is less since the blocks' dimensions are larger. Concrete masonry is affordable and has high fire resistance; hence, it is more popular than other classes.

Composite masonry uses two or more kinds of construction materials for the construction process. It is made out to enhance the appearance of the building and is a versatile process due to the switching of materials based on the economy.

Brick masonry is a well-built form of construction. It has been efficient in our society since the old times, and it is the most durable, energy-efficient, cost-effective, fire-resistant, and sustainable technique to adapt to construction. Brick masonry helps to add a distinctive style to any residential or commercial building with its natural Colour and design.

Vertical joints should be avoided as this would lead to low-strength walls since cracks can quickly emerge along the joints.

It is highly durable and cost-effective than other techniques, and the maintenance costs are minimal compared to others.

The header brick bond is the best and most durable method for a single brick wall since it has alternative stretcher and header courses.

According to the BIS guideline, the standard brick size in India is 190 x cm 9 cm x 9 cm. The dimensions of the brick can be varied to 200 mm x 100 mm x 100 mm when the mortar is thick.

Machine-made bricks are cheaper than handmade ones and are available in various colors and finishings.

First-class burnt clay bricks are the best as they offer the best quality and strength.

The best quality bricks are first-class, have smooth surfaces and well-defined edges, and are suitable for permanent structures. Second-class bricks also have better strength and durability, but they are less smooth or have quality edges than first-class bricks.

Sand lime bricks have a very high compressive strength and are solid and sturdy. They are the best bricks for building load-bearing walls in homes and multi-story buildings.

Red bricks made from organic soil have the potential to cause topsoil erosion over time. On the other hand, AAC blocks use fly ash and help recycle waste products. AAC blocks save energy, time, and money during construction because they are large, lightweight, and resistant to fire and termites.

The average cost of Red brick is 4 to 8 rupees depending on quality and Colour.

For a 12 x 12 foot room, 1713 bricks are required.

To calculate the number of bricks needed per 100 square feet, multiply the structure's square footage by 4.5. 100 X 4.5 = 450 bricks, so 450 bricks are needed per a 100-square-foot structure for a 4.5-inch bricks with a single layer.

A good brick mix would be 6 sand to 1 cement. You can lay 180 bricks per mix with 6 sand (25kg bag) and one cement (25kg bag).

The cost of 500 old bricks is ₹1600.

One thousand bricks cost Rs.1500.

A 1000-square-foot house requires 400 50-kilogram cement bags or around 0.4 bags per square foot of construction.

Red bricks are environmentally benign and decompose since they produce very little trash and have little environmental impact. A red brick's compressive strength is sufficient for any typical building project, and red bricks are readily reusable and recyclable and have strong fire resistance.

You May Also Like To Know:

December 30, 2022 - BY Vismaya Mahendran

December 30, 2022 - BY Vismaya Mahendran